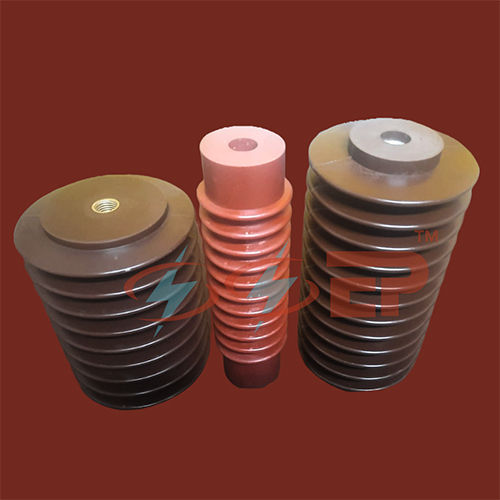

Epoxy Insulator

Product Details:

Epoxy Insulator Price And Quantity

- 1500 INR/Unit

- 1500.00 - 2000.00 INR/Unit

- 10 Unit

Product Description

"Epoxy Insulator 45" likely refers to a specific type of epoxy insulating material with a Shore hardness rating of 45. Here's an overview of what this might entail:

1. Epoxy Insulator Epoxy insulators are electrical insulation components made from epoxy resin, a thermosetting polymer known for its excellent electrical insulation properties, mechanical strength, and thermal stability.

2. Shore Hardness Shore hardness is a measure of the resistance of a material to indentation or penetration by a harder object. The Shore hardness scale is commonly used for elastomers and polymers. A Shore hardness of 45 indicates a material with moderate hardness, falling in the mid-range of the Shore hardness scale.

3. Application Epoxy insulators with a Shore hardness of 45 may be suitable for various electrical insulation applications where a balance of flexibility and rigidity is required. They could be used as insulating spacers, supports, or barriers in electrical equipment such as transformers, circuit breakers, switchgear, and motors.

4. Properties Epoxy insulators with a Shore hardness of 45 are likely to exhibit properties such as:

- Good electrical insulation: Effective at preventing electrical conduction and breakdown.

- Mechanical strength: Able to withstand mechanical stress and load-bearing requirements.

- Thermal stability: Resistant to heat and temperature variations encountered in electrical applications.

- Chemical resistance: Able to withstand exposure to oils, solvents, and other chemicals commonly found in industrial environments.

5. Manufacturing Epoxy insulators with specific hardness ratings are typically manufactured by mixing epoxy resin with curing agents and additives, followed by molding or casting into the desired shape. The curing process involves applying heat or chemical catalysts to promote cross-linking and solidification of the resin.

6. Selection When selecting epoxy insulators, it's essential to consider factors such as:

- Electrical requirements: Voltage, current, and insulation resistance.

- Mechanical requirements: Load-bearing capacity, dimensional stability, and impact resistance.

- Environmental conditions: Temperature, humidity, and exposure to chemicals or UV radiation.

- Regulatory compliance: Ensuring compliance with relevant industry standards and safety regulations.

7. Installation Proper installation of epoxy insulators involves ensuring adequate clearance, spacing, and support to maintain electrical insulation and mechanical integrity. They should be securely mounted or attached to prevent movement or damage during operation.

Overall, epoxy insulators with a Shore hardness of 45 offer a balance of electrical insulation and mechanical strength, making them suitable for various applications in electrical equipment where moderate hardness and flexibility are required. It's essential to consult with manufacturers or suppliers to ensure that the specific epoxy insulator meets the requirements of the intended application.

Other Products in 'Epoxy Insulator' category

|

SRI SURYA ENGINEERING PRODUCTS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |